Generally, a business is looked upon as developing and selling Insurance Accounting products and earning profits. The raw materials required for the product are transformed through specific processes, and finally, products are developed for sale in the market. This transformation requires money, utilities and many other factors.

- Manufacturing overhead significantly influences total costs, and managing these overheads effectively can lead to improved profitability.

- Social media has revolutionized the way businesses interact with their customers.

- Once you assess conversion, you can use the information to better allocate your budget and improve returns.

- First of all, you should know the total amount of money spent on a campaign.

Cost of Goods Sold: Definition, Formula, Example, and Analysis

- But it is not 50% complete with respect to the direct materials themselves.

- If all the product units are the same, each product unit is probably responsible for the same amount of overhead cost.

- This costing formula is used in cost accounting by those running manufacturing businesses or any company producing goods.

- Conversion costs significantly impact product pricing as they form a substantial portion of production expenses.

- Tangible components—such as raw materials—that are needed to create a finished product are included in direct materials.

- Direct labor costs include the salaries, wages, and benefits paid to employees who work on the finished products.

- And the better conversion rate is sure to make way for a better cost per conversion.

Direct labor costs include wages, salaries, and benefits paid to workers who are directly involved in the production process. Understanding conversion costs is crucial for accurate pricing, budgeting, and financial planning in manufacturing, as they significantly impact overall production costs. Conversion costs are essential for accurately pricing products, managing expenses, and optimizing production processes. They offer insights into the efficiency of manufacturing operations and potential areas for cost reduction.

Prime cost formula

However this unit probably may already have most if not all of its direct materials, i.e. ~100% complete with respect to direct materials. 100% of the wood that needs to be painted, 100% of the clay that needs to be baked, or 100% of the metal that needs to be polished is already on the assembly line. It might be 50% complete with respect to the conversion process that transforms those raw materials into finished products. But it is not 50% complete with respect to the direct materials themselves.

- Yes, both fixed and variable overhead costs should be included in the calculation of manufacturing overhead.

- If the cost of flour is $1 per kg, the daily direct material cost for flour is $100.

- They want to set the right pricing to attract customers while ensuring profitability.

- So the number of units transferred is the same for material units and for conversion units.

- The management team wants to reduce the time it takes to produce each widget to increase overall output.

Is conversion cost the same as total manufacturing cost?

The extra step is to directly add beginning WIP cost to the units completed (see cells D6, D13, and D20 in the above figure). The direct materials aren’t used until midway through the process. Appropriately, then, process costing pools costs at the process-level (which usually means its pooled at the department-level) rather than being pooled at the job-level or the unit-level. Remember that conversion cost varies across industries and production methods, so adapt the concepts to your specific context.

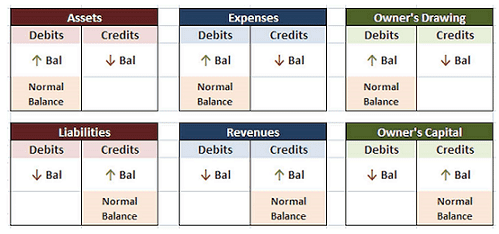

Prime costs and conversion costs are relied upon heavily in the manufacturing sector to measure efficiency in the production of a product. Prime costs are expenditures directly related to creating finished products, while conversion costs are expenses incurred when turning raw materials into a product. Conversion costs consist of direct labor and manufacturing overhead.

2.1 Overview of Process Costing

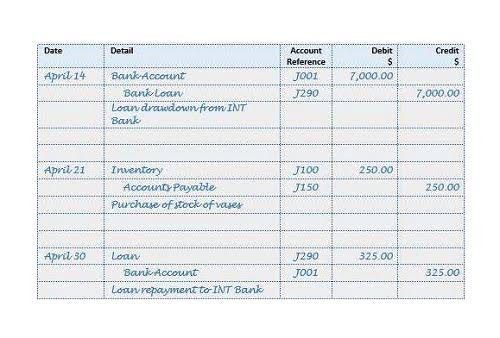

In summary, trial balance calculating conversion cost involves considering direct labor, direct material, and manufacturing overhead. By managing these components effectively, businesses can enhance their competitiveness and financial performance. Direct labor cost refers to the wages and benefits paid to workers directly involved in the production process. These workers operate machinery, assemble products, and perform other tasks that directly contribute to the final product. For instance, in an automobile assembly line, the wages of assembly line workers and machine operators constitute direct labor costs.

Can I include fixed and variable overhead in manufacturing overhead?

First of all, you should know the total amount of money spent on a campaign. Then all you need to do is simple division, and you have your answer. Direct labor costs are the same as those used in prime cost calculations. They invested ₹2,00,000 in galvanised iron sheets, ₹1,50,00 in aluminium sheets, ₹80,000 on SBR tyres, and paid ₹1,00,000 as employee wages. Imagine an e-commerce company that wants to increase its conversion rate (the percentage of website visitors who make a purchase). The original checkout flow has multiple steps, including account creation, shipping details, and payment information.

Q4. Why is tracking conversion costs important for businesses?

To plan the production budget, the conversion cost per unit can be multiplied by the expected number of units to be produced in the future. Some other examples of manufacturing overheads are insurance, building maintenance, machine maintenance, taxes, equipment depreciation, machining, and inspection. To calculate a conversion cost, add together the direct labor cost and the manufacturing overhead. Enter the total direct labor cost and the manufacturing overhead into the calculator to determine the conversion conversion costs cost. Conversion cost is the cost incurred by any manufacturing entity in converting its raw material into finished goods capable of being sold in the market. It usually includes the total value of labor cost and other applied overheads like factory overheads, administrative overheads, etc.

Thus, each cost concept provides a somewhat different view of the costs incurred to create products, though both concepts include the cost of direct labor. This means that the toy company spends $10 on direct labor and manufacturing overhead for each doll it produces. How to use conversion cost for cost accounting purposes, such as assigning costs to products, inventory valuation, and variance analysis.